Offer inquiry

Injection moulding machines for packing

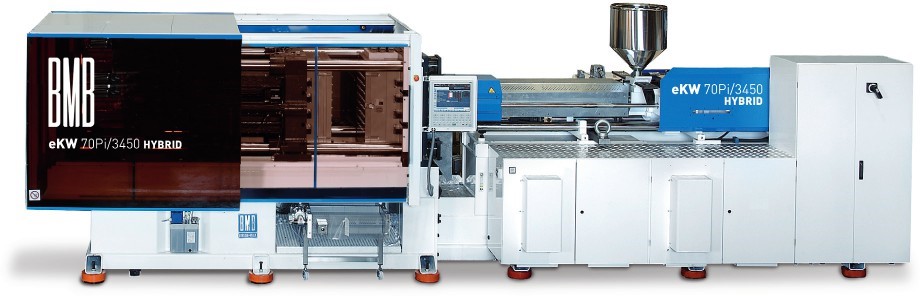

BMB is an innovative company based in Italy, known for making high-quality machines for the production of thin-walled parts and a strategy focused on short cycle times and low energy consumption. Thanks to its consistent quality policy, it has become a world leader. The manufacture of injection moulding machines is a very precise and careful process, and is carried out using the most sophisticated technology by highly experienced technicians. All examinations and final tests of the machines are carried out thoroughly and meticulously every time. All these measures make BMB machines safe and excellent in every respect. Nothing is left to chance. BMB is organised into four lines covering three production facilities. The first two plants are dedicated to the assembly and testing of KW160-3500 tonne machines, eKW100-1150 tonne Full Electric machines and Hybrid eKW160-2200 tonne machines.

In the third, brand-new unit, we are assembling and testing very large KX-series machines with a short-circuit force of more than 2000 tonnes.

We offer top-of-the-range high-speed plastic injection moulding machines from BMB, equipped with numerical control and a touchscreen panel for full control of the production process. Our injection moulding machines are distinguished by advanced process control and the ability to manage speeds, pressures, temperatures and other values, making them ideal for the production of plastic packaging.

Features Distinctive

- Numerical control with touch panel

- Advanced process control

- Full control of speed, pressure, temperature, etc.

- High performance and speed

Diversity Solutions

We offer electric, hydraulic and hybrid injection moulding machines to suit different needs and preferences. Whatever the choice, we guarantee the highest quality and efficiency in production.

Compatibility z Standards EU

All our injection moulding machines comply with current European Union regulations, ensuring safety and meeting regulatory requirements.

With this design, higher opening and closing speeds can be achieved while ensuring perfect parallelism. In addition, longer opening strokes and zero deflection of the pressure plates are inherent features.

The special geometry of the articulating mechanism means that the clamping force is not only applied to the centre of the mould, but is evenly distributed over the entire mould surface.

meet all requirements, with machines ranging from 160 tonnes to 2,200 tonnes.Thanks to the special KW fastening system, plate deflection is eliminated, perfect parallelism is ensured and longer opening strokes are an added advantage.

The movement of the plate is by means of special recirculating satellite roller screws with direct linear drives, which provide high load capacity and improved performance. The reliability and rationality of the machine has been increased thanks to a reduced footprint, brushless motors, liquid cooling and optimum cleanliness of the mould area.

Contact

Dębska Wola, ul. Pińczowska 11

26-026 Morawica

Poland

36-062 Trzebownisko

Poland